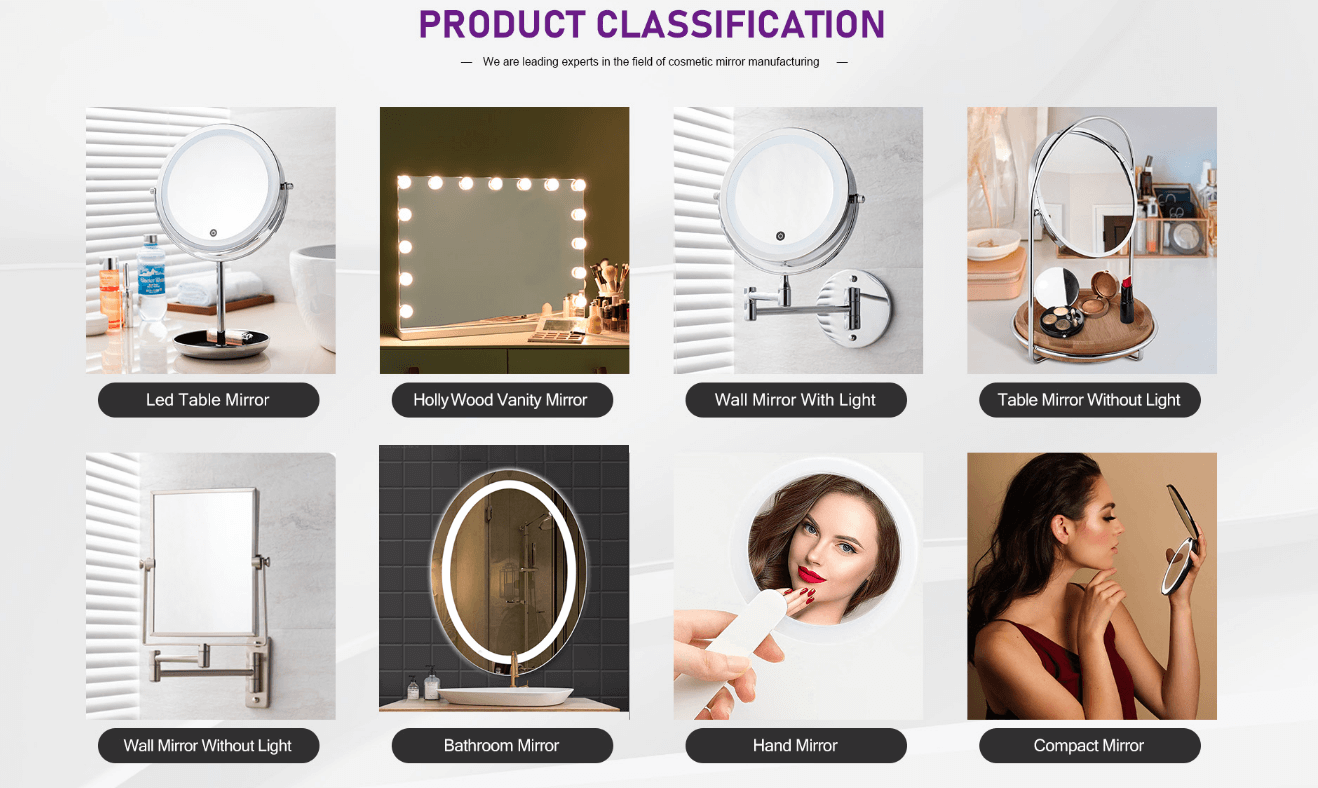

How to make LED Vanity Table Mirror?

In recent years, people have increasingly higher requirements for product functions, and mirrors are one of them. From the original use for decoration in 600 BC to the present, it has focused on the function of lighting, giving consumers better daily skin care and make up use. This article will start from the following points to visually analyze the manufacturing process of the mirror.

This article is aimed at the classic 7 inch with light for a detailed description of the article.

(Attached is the LED vanity table mirror for analysis)

1. From a piece of iron to a smooth mirror appearance

2. From a piece of glass to a mirror that reflects your beauty

3. From a string of lamp beads to giving soul to the illuminated mirror

4. From parts to the birth of finished products

1. From a piece of iron to a smooth mirror appearance

As a mirror manufacturer, we divide into several workshops to arrange the manufacturer of the mirror, and then assemble the finished product. Electroplating the mirror frame and pillars is the first step.

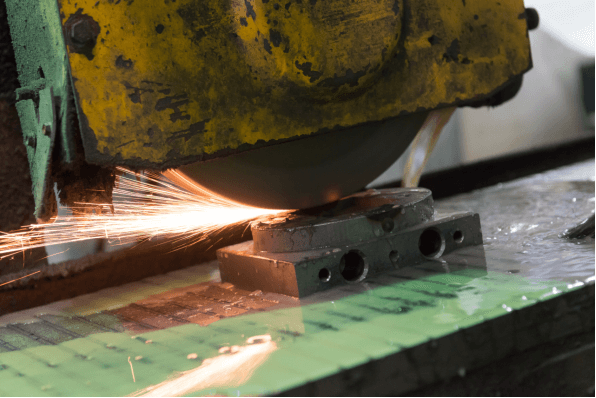

First, the purchase department will order one of the most important raw material for mirorr appearance- iron, It is a large iron roll and then QC team will check the quality.When the quality inspection is correct, they will be placed in the hardware workshop to wait for cutting and punching.

We have mirror hardware molds for various sizes, pillars,mirorr tube and opeartion staff will have the cutting and punching by the machine.

For each component of mirror will have our own operation workers for the punching and cutting includes mirror frame, mirror tube, mirror bottom and hole punching.

After completion, we will send it to the polishing factory for polishing . Polishing is to make the surface of the iron smoother, so that the effect of electroplating will be better.

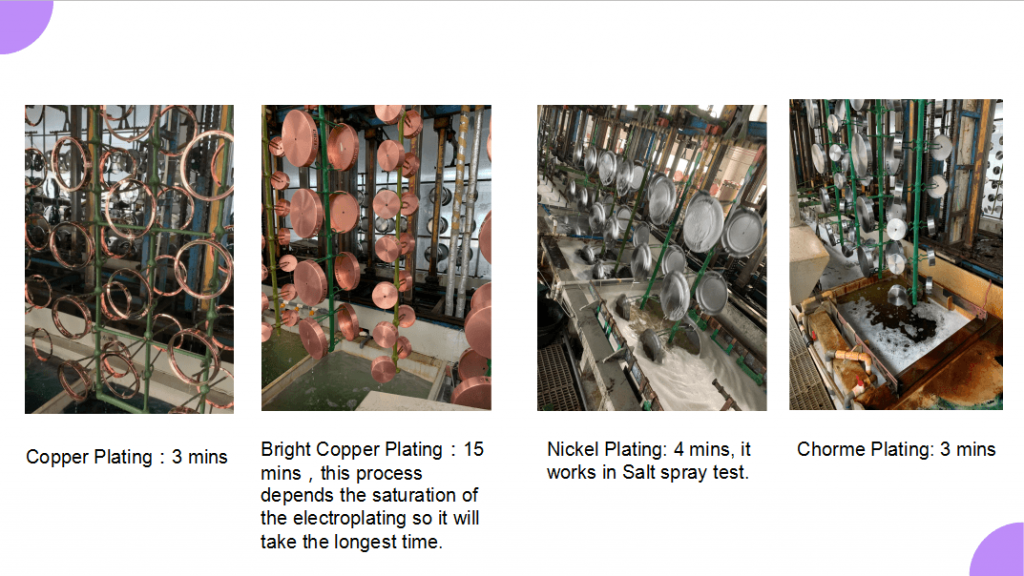

Next step we will have the most important process for chrome electroplating. We will experience about 52mins. Because each step we will have the clean water for cleaning. And after the water cleaning, we will move to the next step electroplating.

After completing the electroplating process, we put the semi-finished materials into the warehouse and wait for other materials to be ready for online installation

Tracking back to the mirror history, people make mirrors from 600BC. And they used polished obsidian at first but because of the expensive raw materials that most of people did not commonly use the mirror until the Contemporary mirrors appearead in Late Renaissance.After the gradual optimization in the later stage, the mirror was put into use as a daily necessities of the family.

Justus von Liebig discovered the chemical process of coating the surface of glass with metallic silver in 1835. Metals can be deposited directly through chemical reactions, so that a thin layer of metallic silver is plated on the glass. He applied a solution of silver nitrate in ammonia to the glass and exposed it to formaldehyde vapor. The silver nitrate is transformed into a thin layer of metallic silver adhering to the glass.

By the way, The mirror can also be made by coating a layer of aluminum on the glass. Using modern technology, aluminum powder can be evaporated and deposited on the glass in a vacuum chamber, and the metal coating is supported by a waterproof coating.

This article is based on Silver-plated or sprayed with a thin layer of silver or aluminum on the back of the glass plate. To ensure the strictly required quality of the products and environmental protection, our mirror glass is purchased from the Taiwan glass manufacturer which is adopted the Japanese Technology. It can achieve the High definition and without distortion.

Finishing the mirror glass, we spray a extra thin layer of green to avoid the mirror light transmission. For better light reflection, we will stick a concentrating sliver sticker which can be totally cover the green layer. With these three layers, we can have a HD glass and gaurantee the mirror quality.

2835 LED light strip perfects the mirrors

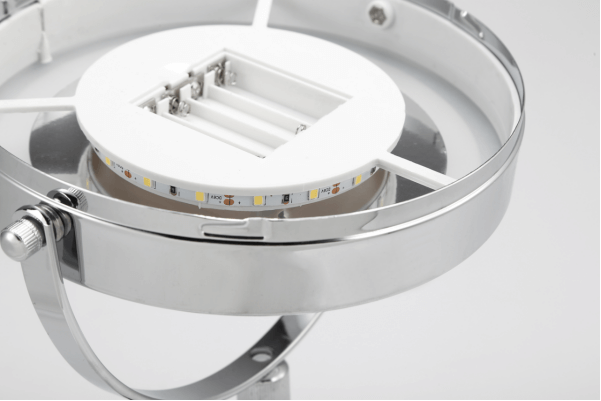

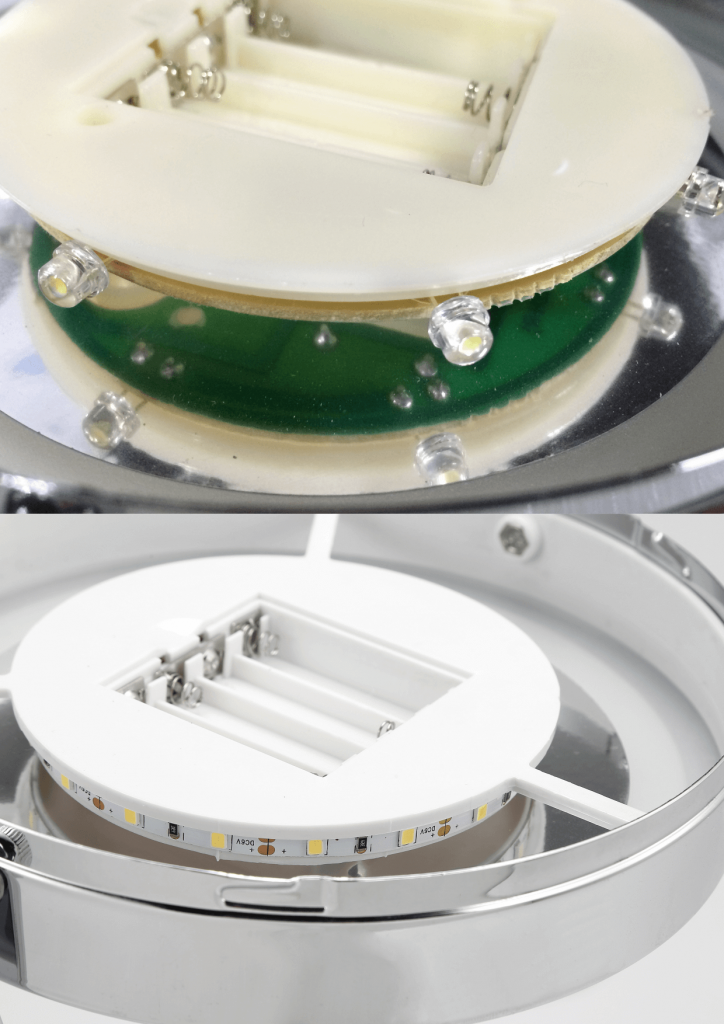

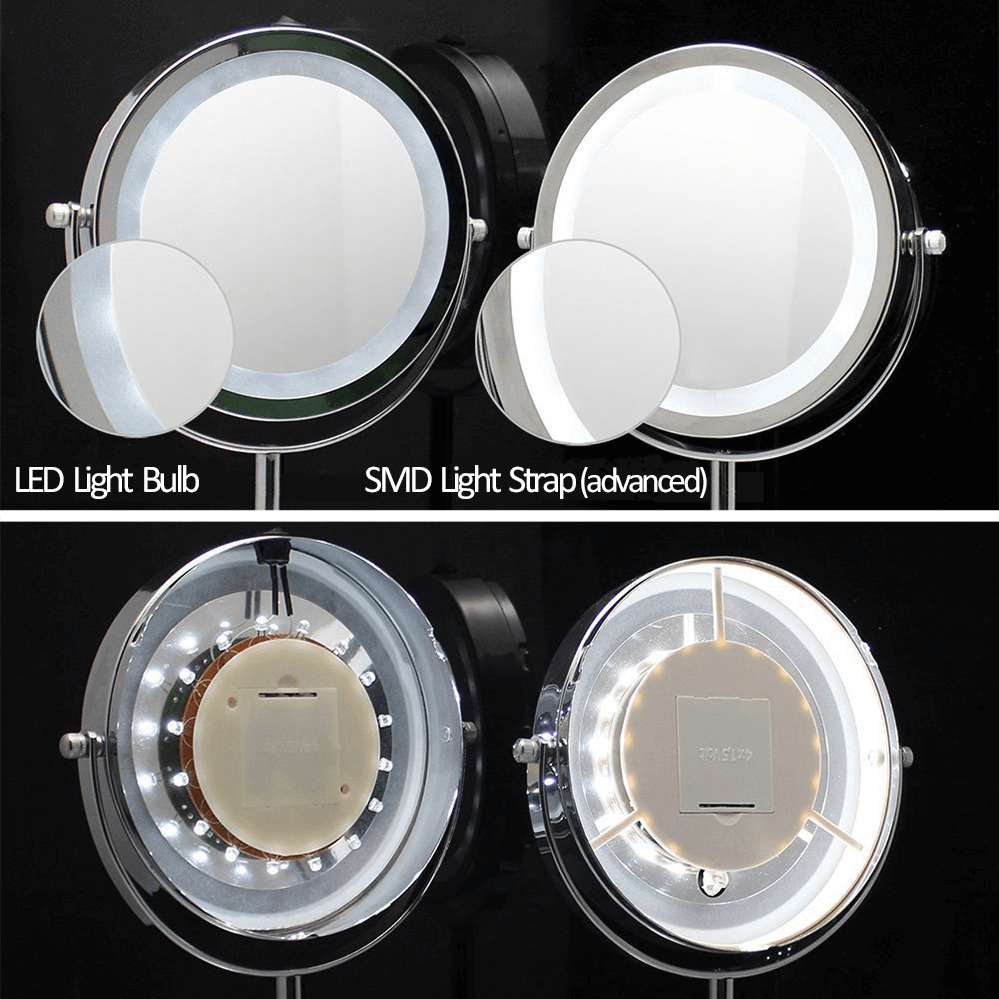

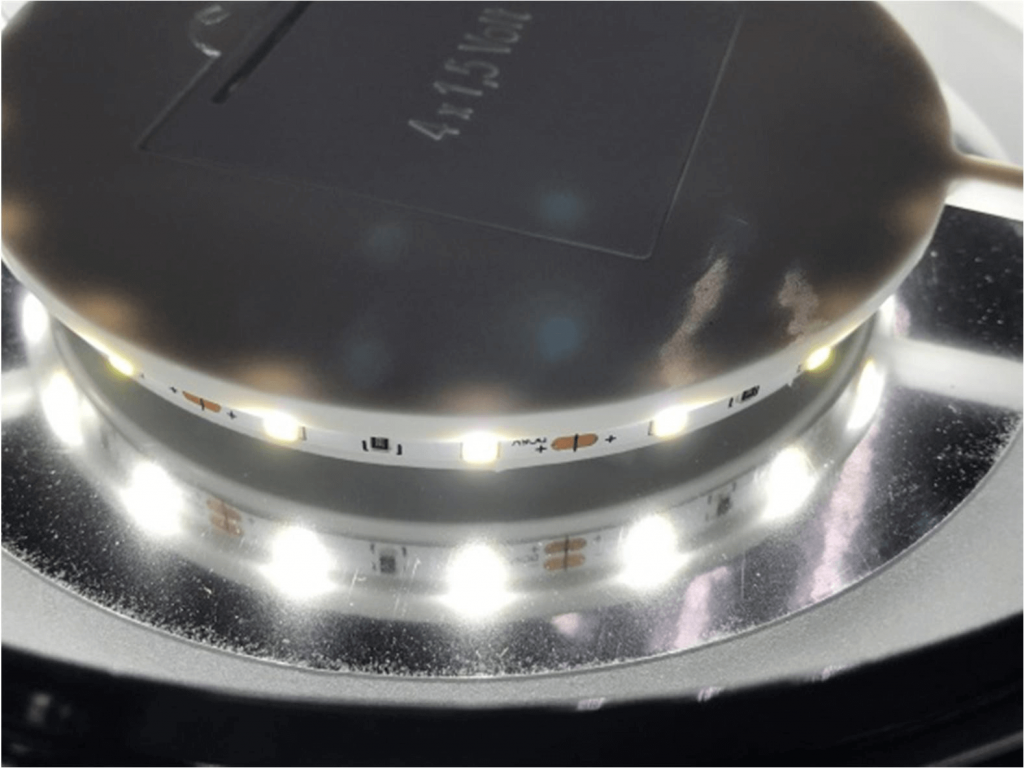

There is not doubt that LIGHT is the spirit. So next step we will have a detailed look at the LED mirror structure inside. When screw the mirror frame, we can easily open the mirror inside. And there is a white battery box for battery. And we will put the 2835 SMD light strips with 18pcs SMDs hidden under the battery box. 2835SMDs can be more light stable, brighter and high efficiency.

We are the witeness and leader of the development of cosmetic mirror industry. You can see the development of the mirror from a simple mirror to be the popular lighted mirror. You can use our cosmetic mirror not only for easy makeup but also as a light for you in the dark. And the technology innovation on light are still going on by our engineer effort. Our SMD light strips update from CRI75 to CRI900, achieves LUX900-1000.

So it is the reason why our table mirrors are popular all the time because we focus on the continues progess and effort.

Next step is to assemble the mirror in the production line. All the semi-finished products will put in the production line in order.

We will arrange around 20-30 production workers in the line and they will seperately be responsible for one production process. We will have the semi-finished products-light test- the Y-shape assembly- Mirror Bottom EVA sticking – Finished product qulity check- PE bag or bubble bag packing- manual or intruction putting- white box or color box packing-master carton packing. During the whole assmbly, we will have double check the light and mirror in order to provide the best service for all the clients.

After good production, we will arrange our QC team for quality check based on AQL2.5/4.0.

We will test the mirror light, the plating, the EVA anti-Slip Test, weight confirmation to ensure the mirror quality.

When the QC pass the inspection,we can load our goods and arrange for the shipment.

LED table mirrors is still a popular trend these year in the market. Having the detailed introduction, we will know better about the table mirror with light production process. We do not stop the light upgrade as our aim is to perfect the lighted mirror, perfect the mirror user experience. And in the future, we will still have more technology innovation on not only the light function, but also can charge your phone, Bluetooth connection, smart skin testing,etc. We will tell you and make you trust that “It is more than a mirror”.

Follow us on Facebook